Muffle Furnace

The Test Your Product Muffle Furnace allows you to evaluate materials and products thermally, thereby assessing performance and durability parameters. In reality, products are put under exposure to many conditions with high temperatures. You can evaluate material properties with the help of a Muffle Furnace, which could optimize product designs and quality standards that guarantee the survival of products under extreme Muffle Furnace, temperatures as well as environmental stresses.

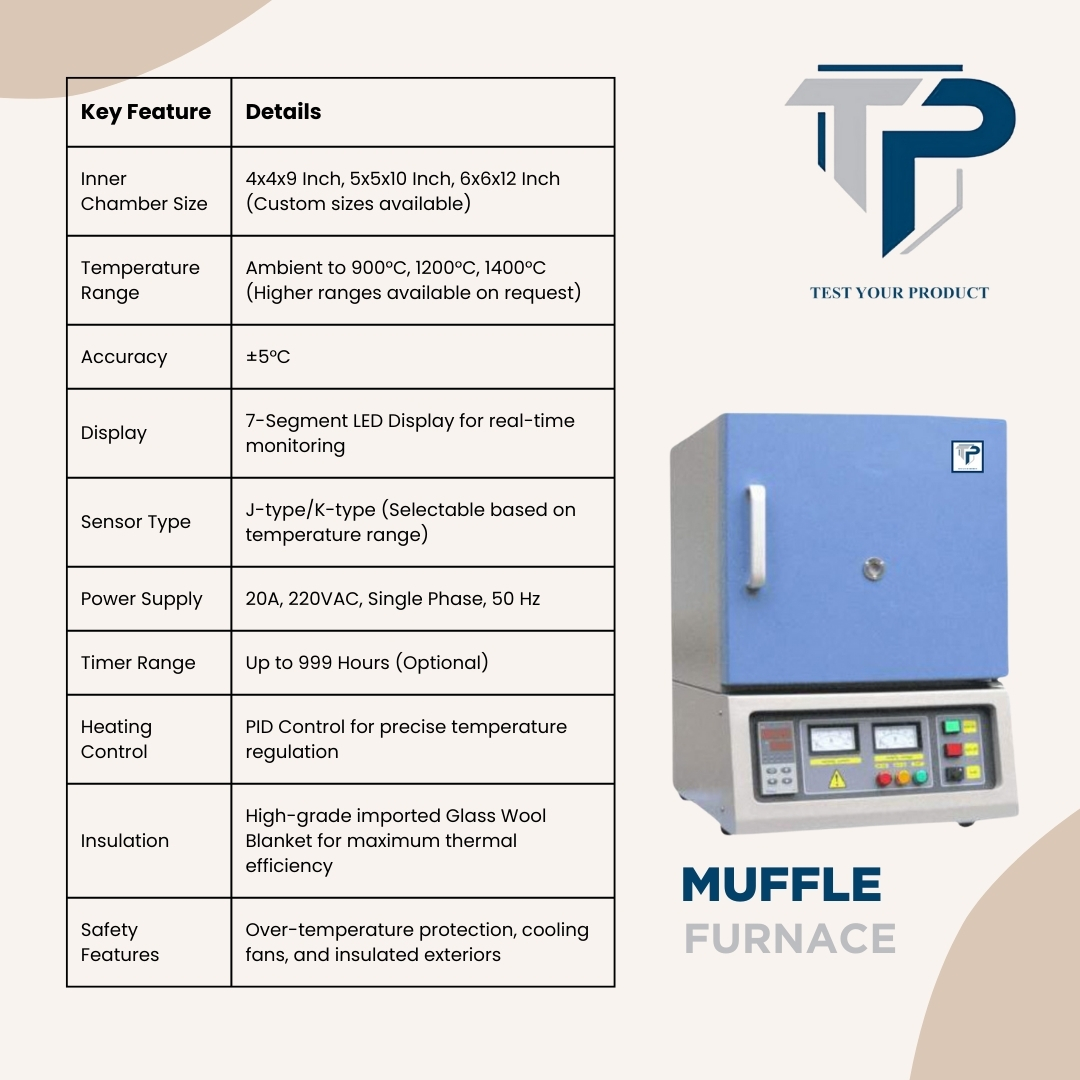

Product Details

| Key Feature | Details |

| Inner Chamber Size | 4x4x9 Inch, 5x5x10 Inch, 6x6x12 Inch (Custom sizes available) |

| Temperature Range | Ambient to 900°C, 1200°C, 1400°C (Higher ranges available on request) |

| Accuracy | ±5°C |

| Display | 7-Segment LED Display for real-time monitoring |

| Sensor Type | J-type/K-type (Selectable based on temperature range) |

| Power Supply | 20A, 220VAC, Single Phase, 50 Hz |

| Timer Range | Up to 999 Hours (Optional) |

| Heating Control | PID Control for precise temperature regulation |

| Insulation | High-grade imported Glass Wool Blanket for maximum thermal efficiency |

| Safety Features | Over-temperature protection, cooling fans, and insulated exteriors |

Overview:

The Muffle Furnace manufacturer, Test Your Product involves evaluating the thermal resistance and durability of materials and products in a controlled environment. Plastic and Polymer Testing equipment simulates actual high-temperature conditions found in the field and is quantified to provide useful information about material behavior concerning actual performance. Companies use such machines in material science, research, and quality assurance, and they obtain extra benefits from knowing those companies have made and stood for quality and integrity in their products.

Working of Muffle Furnace:

The test specimen is typically a sample of material or product prepared for testing. Mount the specimen to the furnace following protocol. The Muffle Furnace suppliers providing the instrument is equipped with a temperature-controlled chamber that simulates high-temperature conditions in the field to obtain an accurate measurement of the thermal properties of the specimen.

Establish test conditions, heating rate, and dwell time and perform the test. During that period, Muffle Furnace evaluates specimen thermal resistance durability, and behavior at high temperatures; parameters may then be changed to simulate various thermal loading conditions.

The conditions of the object after testing are monitored with temperature sensors, cameras, and several other monitoring systems. The Muffle Furnace will be very essential in materials science, research, and quality assurance. Further, predicting problems associated with thermal performance will greatly improve material selection and optimization of the designs of products for better efficiency.

Benefits of Muffle Furnace:

At Test Your Product, our Muffle Furnace offers numerous benefits to materials scientists, researchers, and quality assurance teams:

- Thermal Performance and Reliability: Provide thermal resistance and durability assessment to materials at varying temperature conditions.

- Detect potential design weaknesses for further improvements by simulating a real thermal scenario in application.

Improved material selection and design optimization for product standards and reliability.

- Industry Standards Compliance: Materials tested in simulations compliant with ISO and ASTM specifications.

- Demonstrating quality and reliability builds brand reputation leading to customer trust and loyalty.

- Cost reduction through early detection of potential material failures against costs related to product testing, repair, and replacement.

- The fulfillment of quality and reliability standards gives its share in customer satisfaction at the same time with keen retention

A muffle furnace is essential for thermal resistance testing, ensuring material durability in extreme high-temperature conditions. Leading muffle furnace manufacturers design advanced models for research laboratories, material science, and quality assurance. These testing furnaces comply with ISO and ASTM standards, enhancing product reliability and efficiency. Industries benefit from early material failure detection, reducing costs related to repairs and replacements. By simulating real-world thermal conditions, a muffle furnace supplier helps optimize material selection and product design. Investing in a high-quality muffle furnace strengthens brand reputation, customer trust, and long-term product performance.

Specification:

| Inner Chamber Size | 4 x 4 x 9 Inch, 5 x 5 x 10 Inch, 6 x 6 x 12 Inch (Other size available) |

| Display | 7 Segment LED display |

| Accuracy | ± 5°C |

| Least Count/Resolution | 1°C |

| Sensor | J-type/K-type as per selection of range |

| Power | 20A, 220VAC, Single phase, 50 Hz |

| Timer Range | Up to 999 HRS (Timer optional) |

| Temperature Range | Ambient to 900ºC, 1200 C & 1400 C as on request |

Features:

- Temperature is sensed through a J-type sensor. Transformation of ambient temperature to required test rates in short intervals. Highly accurate test results under uniform temperatures. PID Control for Temperature.

- Maximum Use of thermal efficiency by insulation means. High-grade density imported Glass Wool Blanket insulation. SSR-based heaters Auto tuning Advance PID controller.

- Homogenous Heating: The design ensures the even distribution of heat throughout the chamber.

- Digital Display: Real-time monitoring of temperature and process duration. Programmable Functions: Multi-step programmable controllers for complex heating scenarios.

- Compact and Durable: Space-saving simplicity with a continuously solid structure. Safety Features: Over-temperature protection, cooling fans, and insulated exteriors ensure safe use.

Our muffle furnace is designed for precise high-temperature testing, ensuring thermal efficiency and uniform heating. It features a J-type sensor for accurate temperature control, transforming ambient temperature quickly. The PID controller and SSR-based heaters provide auto-tuning capabilities for stable performance. Muffle furnace manufacturers use high-density glass wool insulation to maximize efficiency. A digital display allows real-time monitoring, while programmable functions support complex heating processes. Its compact, durable design includes over-temperature protection, cooling fans, and insulated exteriors for safety. Contact leading muffle furnace suppliers for details on muffle furnace price and specifications.

Q1. What is a Muffle Furnace used for?

The laboratory heating apparatus called the Muffle furnace maintains different processes such as heat treatment thermal testing and material synthesis with features including ashing and calcination. The muffle furnaces utilize heat to transform materials at temperatures exceeding thousands of degrees Celsius (starting from 1800°C) while effecting physical modifications such as annealing hardening and tempering. Muffle Furnace serves multiple functions including ceramic and glass processing and R&D operations and quality control aspects that turn it into a vital laboratory instrument for both research institutions and aerospace industries along with automotive manufacturing facilities.

Q2. What materials can be processed in a Muffle Furnace?

The Muffle Furnace enables the generation of heat for processing more than 20 different materials including metals and ceramics alongside glass materials composites and powders along with fibers and organic substances. A Muffle Furnace performs heat treatment along with firing, sintering, melting, ashing, calcination and thermal decomposition which together make it one of the most useful devices across various research and industrial applications.

Q3. How does a Muffle Furnace maintain uniform temperatures?

A Muffle Furnace provides uniform temperature through insulation along with heating elements complemented by an advanced temperature control system. The test chamber of the muffle furnace must function to eliminate temperature gradients according to standard requirements yet certain models utilize an air circulation system to establish balanced temperature distribution for accurate and trustworthy results.

Q4. What industries commonly use Muffle Furnaces?

The Muffle Furnace manufacturer in India operates in various segments such as aerospace manufacturing along with automotive industries and ceramics applications in glass production and materials science laboratories. These machines apply their capabilities to calcination processes while also serving ashing operations and thermal decomposition of multiple chemicals and pharmaceutical products. Muffle Furnaces serve for research purposes as well as experiments among universities and scientific research institutions.

Q5. What is the maximum temperature a Muffle Furnace can reach?

The temperature range of A Muffle Furnace extends to 1800°C (3272°F) depending on its specific model along with the selected configuration options. Modern Muffle Furnaces reach up to 2000°C (3632°F) with their advanced features which enable these systems to accommodate multiple research and industrial developmental requirements.

0 reviews

Write a Review